What Is a Chemical Feed System?

A chemical feed system is a vital part of many industrial processes. Whether you’re treating water, managing pH levels, or adding specific chemicals to a process, a chemical feed system ensures it performs the job with precision and safety. These systems are used in industries like power generation, oil and gas, data centers, food and beverage, and more.

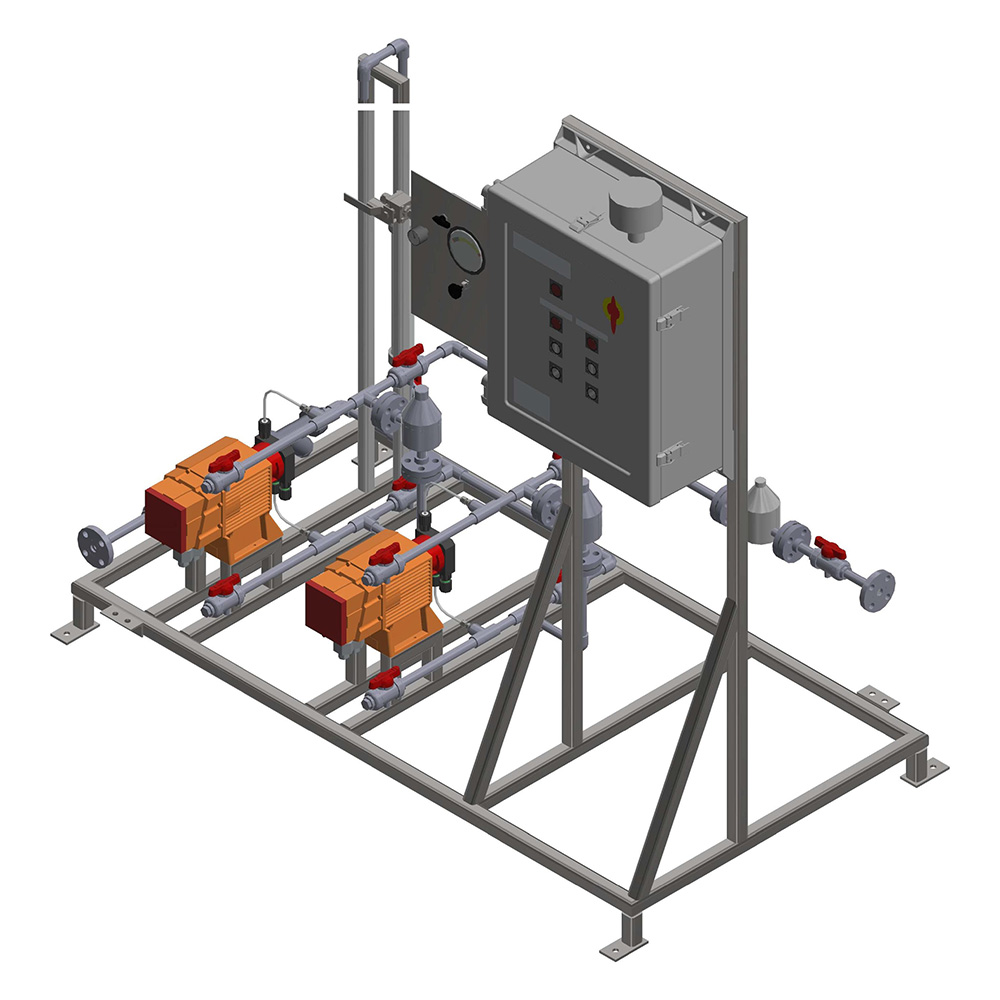

At its core, a chemical feed system includes pumps, tanks, pipes, and controls that work together to deliver the right chemical at the right time and amount. It’s about keeping operations efficient and people safe.

Why Chemical Feed Systems Matter

A well-designed chemical feed system helps prevent scaling, corrosion, and microbial growth. It also protects process integrity, improves uptime, and extends equipment life.

“Whether it’s boiler treatment, cooling towers, or wastewater treatment, each application relies on the system to perform accurately every day,” says Michael Perry, National Sales Manager at AmeriChem Systems.

Custom vs. Standard—What You Really Need

Not every project needs a custom solution, but many do. Standard feed systems can work in repeatable, low-variation environments like municipal water. But for industrial applications—especially those involving high pressures, tight space, or harsh chemicals, a custom chemical feed system is often the only reliable option.

Perry explains, “Even a small tweak, like a unique flow rate or limited space, can push a system from standard to custom.”

Avoiding Common Mistakes

A chemical feed system can only perform well if it’s properly designed. One of the most common errors engineers make is incorrect pump or material selection. For example, using the wrong material can lead to rapid corrosion and early failure. Overcomplicating controls is another issue, sometimes simpler is smarter.

Early collaboration is key. AmeriChem helps clients avoid costly redesigns by reviewing specs upfront and offering guidance before fabrication begins.

Chemical Feed System: Safety and Compliance Come First

Every AmeriChem chemical feed system is built with safety in mind. That means using UL508A-certified control panels, ASME-compliant pressure vessels when required, and full system testing prior to shipment. Systems are engineered for safe operation, easy maintenance, and long-term reliability.

“We want our clients and their teams to go home with all their fingers and toes,” Perry adds. “It’s about building something you can trust.”

Real-World Example: Precision in Action

In one recent project, AmeriChem delivered a containerized chemical feed system with 1” and 2” socket welded pipe and a customer tie-in connection tolerance of just 1/16 of an inch. It arrived fully tested and ready to connect, saving the client time and reducing costly on-site labor.

Containerized systems like this are plug-and-play. They’re ideal for harsh outdoor environments or tight installation schedules.

Ready to Build with Confidence?

If you’re planning your next project, don’t leave your chemical feed system to chance. AmeriChem designs systems with your specs, space, and safety in mind. From UL, CE, AWS, NEC, NFPA and ASME compliance to reliable performance, they’ve got you covered.

Did you like this post? Visit our Articles Page and follow us on LinkedIn: @AmeriChemSystems. To read more about technology, innovation, and industry insights, just click the ‘Follow’ button at the top of this page.

Here are some of my previous LinkedIn insights:

Design of Suction Piping for Centrifugal Pumps

Boom or Bust? Don’t let your next process plant expansion give you a stiff neck and a busted budget!

Has your Rail Tank Car filling got you going off the rails?

Custom Automation – Machine Highlight: Automatic Filling Machines

Improving legacy process systems: Turn your data reporting wishbone into a backbone