The Need for Safety in a Hydrogen-Powered Future

Hydrogen is playing an increasingly vital role in the global energy transition. Whether it’s through green hydrogen electrolyzers or fuel cells powering clean mobility and energy systems, the use of hydrogen introduces new opportunity and responsibility when it comes to safe, efficient operation.

In hydrogen systems, especially those at high voltages, safety is paramount. Reliable monitoring of equipment voltage, current, and temperature is essential at the stack and string levels. This helps to maintain operational integrity, detect early signs of fault conditions, and comply with the stringent standards that govern hydrogen applications.

Knick Interface and AmeriChem Systems (ASI) have partnered to deliver fully integrated, SIL-rated, high-isolation solutions for hydrogen production and conversion systems. This collaboration ensures customers receive not only precision instrumentation but also safety-compliant enclosures and turnkey integration for demanding applications.

Understanding SIL and Its Relevance to Hydrogen

Safety Integrity Level (SIL) is a fundamental concept in functional safety, used to evaluate how reliably a system can perform its intended safety function under specific conditions. SIL ratings range from 1 to 4, with SIL 4 representing the highest level of risk reduction. These ratings are closely tied to factors like a device’s Mean Time Between Failures (MTBF) and its behavior in fault conditions. In some cases, a device’s high MTBF can demonstrate a sufficient level of reliability, serving as a basis for its inclusion in a SIL-rated system.

To achieve SIL compliance at the system level, every component must meet a corresponding SIL standard, with the system ultimately rated based on its lowest-rated element. SIL-rated devices are also designed to avoid interfering with existing system signals. This ensures clean, predictable communication between components, reinforcing system or device reliability and performance.

In hydrogen systems, SIL compliance is critical due to high-potential DC voltage and the volatile nature of hydrogen. Monitoring and control systems must be able to withstand these conditions while ensuring safe operation, especially in fault scenarios where risk is the highest. Both Knick and AmeriChem Systems align their offerings to meet or exceed these functional safety requirements by utilizing equipment rated for such scenarios.

Measurement Challenges in Hydrogen Environments

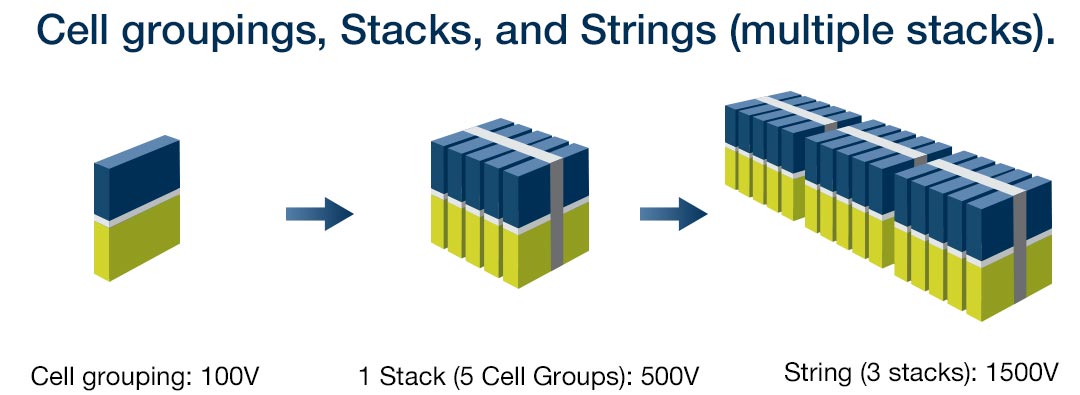

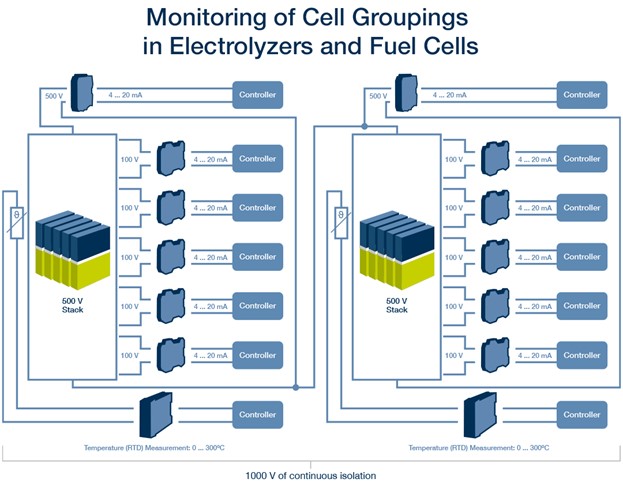

Hydrogen electrolyzers and fuel cell systems operate in demanding high voltage environments. Stack voltages can range from several hundred to several thousand volts, while current levels often reach into the kiloamp range. Because these systems are frequently connected in series, strong electrical isolation is necessary to safely handle the cumulative voltage potential. Accurate voltage and current measurement provide valuable insight into system performance with voltage readings revealing cell membrane health or stack imbalances and current measurements reflecting overall energy conversion efficiency, among other things. Temperature monitoring is equally important, helping to identify thermal events that could signal developing faults or failures. Managing all these variables is complex but essential, accentuating the need for a robust and reliable measurement architecture.

These parameters must be monitored continuously for efficiency tracking, real-time fault detection, and data analysis that supports predictive maintenance and system optimization. Real-time diagnostics enable quicker fault isolation and reduce troubleshooting time during service events as well. Over the long term, reliable measurement also supports compliance reporting and benchmarking, which are increasingly important for projects backed by government funding or emissions targets. This highlights the critical importance of engineering a solution with the highest quality components to ensure proper equipment function.

Knick’s Role in Safe Measurement

Knick Interface offers a range of transducers specifically engineered for hydrogen applications like stack and string monitoring. A standout among them is the P45000, a high voltage transducer certified for use in SIL 2 and SIL 3 systems. With reinforced isolation up to 4.8 kV DC, voltage measurement capabilities up to 4500 V DC, and a T90 response time under 70 µs, the P45000 is built for environments where reliability is non-negotiable. Its compact form factor allows for vertical, horizontal, or DIN rail mounting, and units can even be stacked to save valuable panel space.

Knick also provides current transducers, measuring via shunt, for high-accuracy monitoring. A key offering is the P41000, which delivers current measurements while isolating up to 3.6 kV, making it well-suited for applications such as fuel cell string monitoring, DC bus measurements, and current balancing across stacks. With a response time of under 110 µs, the P41000 ensures accurate current data is captured consistently.

What further sets Knick apart is its long-term durability, reinforced by impressive MTBF ratings which directly support functional safety goals. In addition to voltage and current measurement, Knick also offers temperature monitoring solutions with up to 6.6 kV of continuous isolation. Together, these devices form the backbone of a resilient, high-integrity monitoring system for hydrogen applications.

AmeriChem Systems: From Components to Complete Solutions

While Knick supplies precision measurement hardware, AmeriChem Systems (ASI) transforms these components into a complete monitoring solution. Based in Aurora, IL ASI is an ISO 9001 certified manufacturer and draws on years of experience in areas like water treatment and chemical process skids, ASI designs and fabricates modular systems; including panels, enclosures, and integrated process systems tailored to customer specifications.

These systems are engineered safety platforms that account for any customer need such as voltage or current measurements, isolation to withstand system potential, environmental exposure, and functional safety requirements. Enclosures are available with NEMA ratings suitable for harsh industrial settings and can be designed for Class I Div 2 hazardous location compliance. Whether the application is a pilot-scale R&D setup or a large industrial-scale hydrogen production facility, ASI designs to accommodate any situation without compromising integrity.

Safety is engineered into every level of the project. Redundant sensor architecture, safety PLCs with TUV-certified function blocks, and layered interlock systems are used to ensure each installation meets or exceeds SIL targets. For hydrogen projects, emergency shutdown capabilities, hydrogen leak detection, and system-wide alarm signaling are designed to respond in real time to any abnormal conditions.

Beyond exceeding safety requirements, ASI also supports signal isolation, conversion, and conditioning for seamless integration into PLCs and SCADA systems. Whether it’s Ethernet/IP, Modbus TCP, Profibus, or custom industrial protocols, the data output from an AmeriChem System’s modular equipment arrives cleanly into the operator’s control system, fully tested and ready for start-up.

A Unified Approach to Safety and Performance

When it comes to hydrogen, safety can’t be pieced together as an afterthought. It must be engineered into the system at both the component and system level. The partnership between Knick and AmeriChem brings that philosophy to life. By combining industry leading electrical measurement technology with integrated, compliant system design, hydrogen operators gain a fully supported and safe solution.

This joint approach offers more than just instrumentation or enclosure hardware. It offers peace of mind knowing that each sensor, each enclosure, and each signal is part of a safety strategy. For any operator investing in hydrogen systems, from green energy production to clean transportation, precision and protection is key to long-term success. Contact Knick Interface or Americhem Systems today to see how these ideas come to life.

Contact Us today to learn more about our High Voltage Solutions.