Does your Rail Tank Car filling and level monitoring got you going off the rails?

Do your tank cars constantly need cleaning and spill containment measures due to overfilling? Does your custody transfer method have you doubting your true costs and clients debating the volume they were transferred? ASI has the solution you need!

Wireless Level Monitoring for Rail Cars

Rail tank cars can carry many different commodities, like chemicals, molasses, edible tallow, water, fuel and others. Many commodities are considered extremely valuable materials. When transferring these materials between stationary points and a mobile tank car there can be overfilling or underfilling issues, sometimes resulting in headaches like spill containment, lost revenue or upset customers.

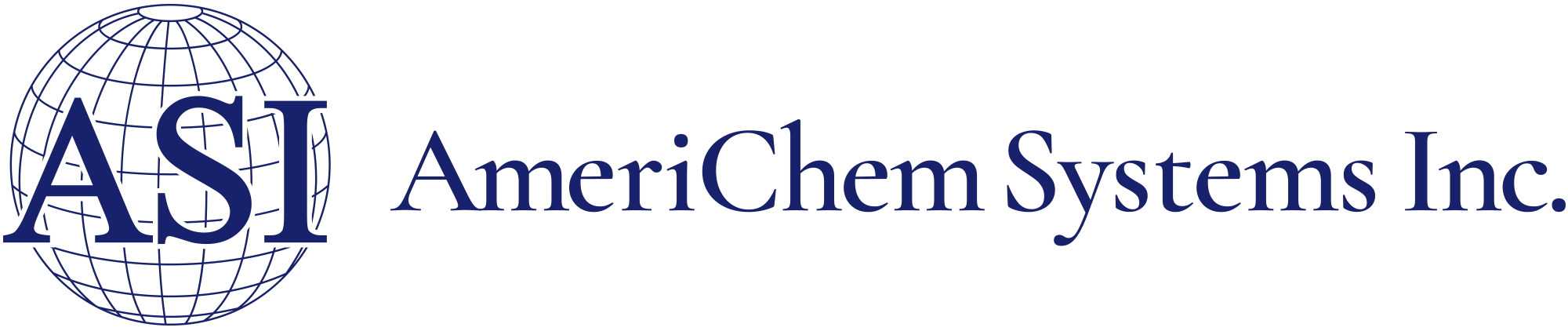

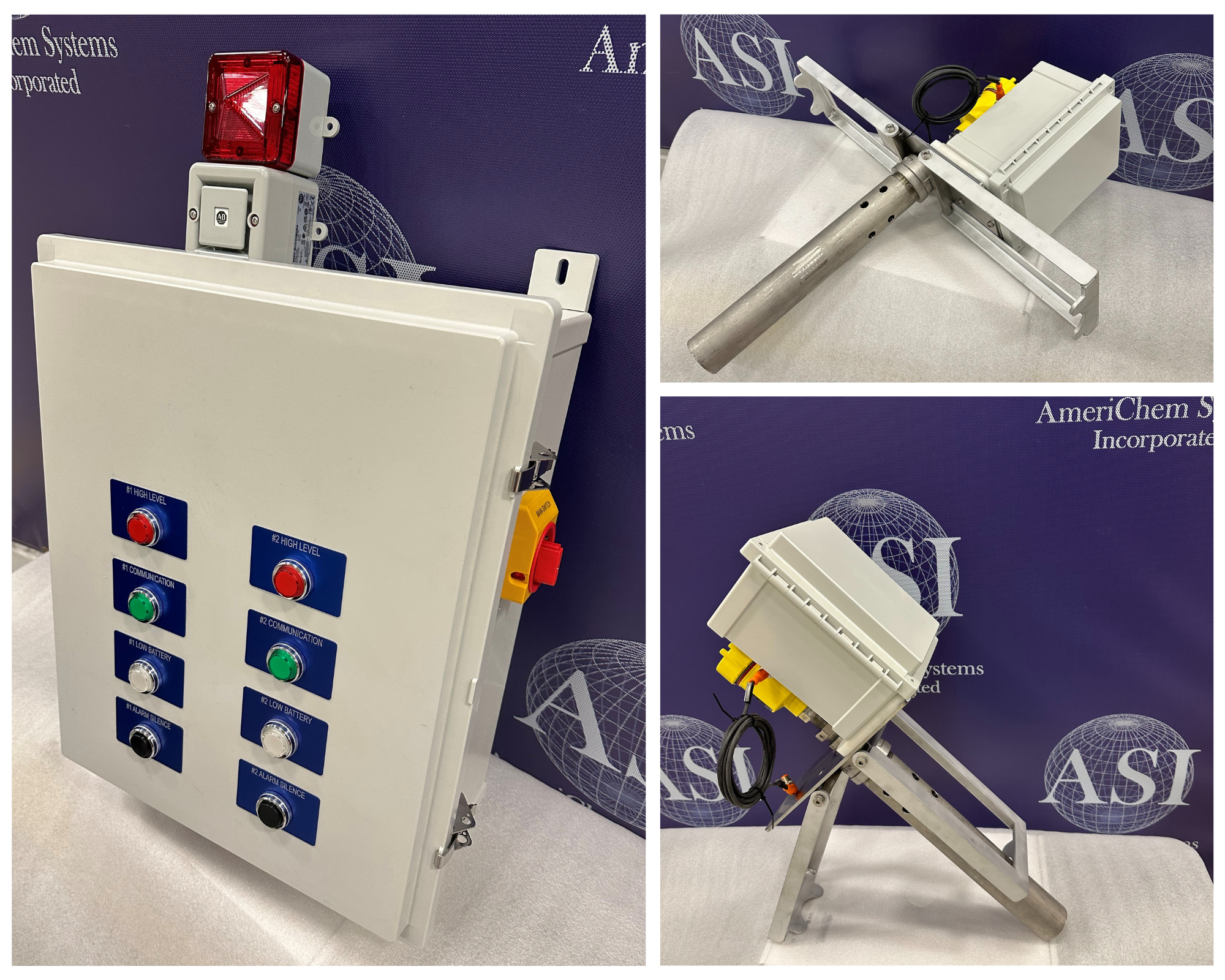

When a local manufacturing company came to ASI and asked if we could help them reduce spill containment problems, we came up with a battery operated high level sensor that could be easily carried up the ladder of a tank car and placed on the top inspection port. This sensor system could operate for up to 8 hours in frigid temperatures and communicated back to a stationary control panel that would shut off the corresponding pump to eliminate their overfilling issues.

When a local manufacturing company came to ASI and asked if we could help them reduce spill containment problems, we came up with a battery operated high level sensor that could be easily carried up the ladder of a tank car and placed on the top inspection port. This sensor system could operate for up to 8 hours in frigid temperatures and communicated back to a stationary control panel that would shut off the corresponding pump to eliminate their overfilling issues.

Now their operations staff can sleep peacefully knowing their filling operations are back on the rails!

Let’s talk about how to make your next remote level monitoring dream a reality!

Contact ASI today to start your next automation or remote monitoring project

#asi #wecandothat #americhemsystems #remotemonitoring #processautomation #processengineering

Did you like this post? Visit our Articles Page www.AmeriChemSystems.com/articles and follow us on LinkedIn: @AmeriChemSystems. To read more about technology, innovation, and industry insights, just click the ‘Follow’ button at the top of this page.

Here are some of my previous LinkedIn insights:

Custom Automation – Machine Highlight: Automatic Filling Machines

Improving legacy process systems: Turn your data reporting wishbone into a backbone

Did you know that most companies get their process expansion projects backwards?