Introduction

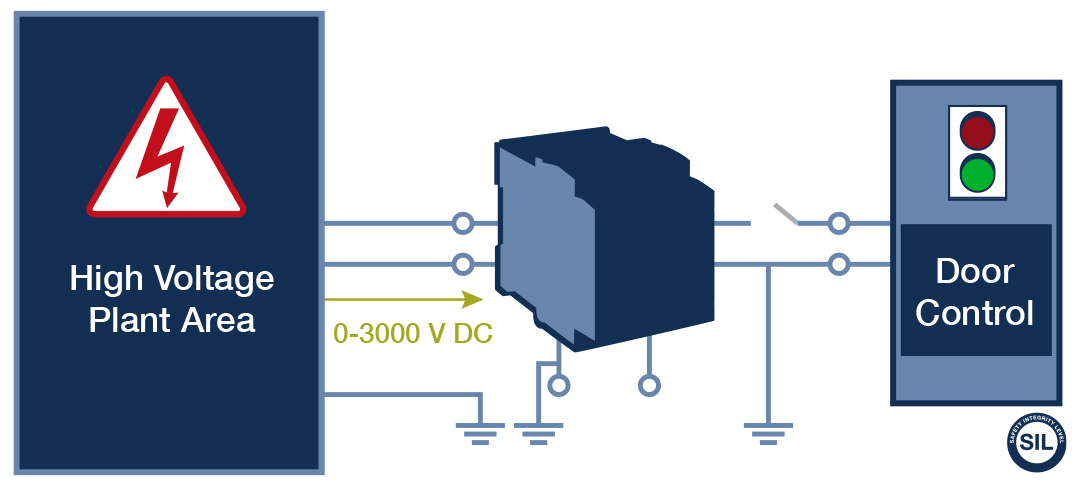

Electrical isolation is a critical concept in electrical system design, ensuring both the safety of personnel and the protection of equipment. This is especially important in high-voltage systems, where precise measurement devices prevent failures. Attention must be paid when designing solutions to isolation specifications. Careful planning in this area enhances safety, reliability, and system longevity.

This article will explain what electrical isolation is, when it’s necessary, and why it is essential in electrical applications.

What is Electrical Isolation?

Electrical isolation involves separating different sections of a system to prevent electrical interference, maintain signal integrity, and protect equipment and personnel from hazards. Isolation can be achieved using several methods, including:

- Transformers:

Electrically separate input and output circuits through electromagnetic induction. - Optical Couplers:

Use light to transfer electrical signals while maintaining electrical isolation.

Each method has its advantages and disadvantages. For instance, transformers provide effective isolation but can be bulky. Optocouplers offer faster response times but may be more sensitive to environmental conditions. Either of these methods can then be used to achieve galvanic isolation. Galvanic isolation prevents direct current (DC) flow between components while allowing the transmission of alternating current signals (AC) and is essential for noise reduction in sensitive devices.

In high-voltage measurement devices, isolation protects sensitive electronics from surges, faults, and noise, preventing system damage and ensuring the safety of both equipment and personnel. There are two types of isolation to be reported for these devices: working isolation and test isolation. Continuous isolation is the maximum voltage a device can handle during normal operation, while test isolation is the voltage it can withstand briefly, typically for one minute. It’s crucial to distinguish between these when designing a system. Misunderstanding these specifications can lead to severe consequences, including component damage and safety hazards. Therefore, accurately identifying the type of isolation is essential for ensuring system safety and reliability.

Types of Continuous Isolation:

Basic vs. Reinforced

- Basic Isolation:

Involves a single layer of insulation, typically used in systems where indirect contact with high voltage is unlikely or other safety measures are in place. This type of isolation is often found in consumer electronics, where the risk of direct contact between the user and the device is minimal. - Reinforced Isolation:

Provides a higher level of protection, equivalent to double insulation. It is crucial in environments where safety is paramount, such as industrial machinery, where operators handle equipment that operates at dangerous voltage levels. Reinforced isolation reduces the risk of electric shock, safeguards sensitive components, and ensures compliance with strict safety standards, enhancing workplace safety and minimizing liability.

When is Isolation Necessary?

Isolation is essential in systems where high-voltage components are present, such as power distribution and industrial automation. It separates hazardous potentials from control systems and low-voltage devices, ensuring operational safety and preventing damage.

Isolation is also critical in applications requiring sensitive measurements, such as battery monitoring or hydrogen fuel cell systems. In these contexts, isolation ensures that noise and interference do not corrupt data, maintaining accuracy and data integrity.

Compliance with safety standards like UL and EN often mandates the use of isolation, especially in high-risk environments. Solutions should be designed to meet and exceed these stringent standards through rigorous testing and certification processes. This ensures that the system will provide adequate levels of safety and protection.

Why is Isolation Important?

Proper electrical isolation is vital for preventing electric shocks and protecting equipment. In high-voltage environments, isolation shields personnel from dangerous voltages and protects downstream components from electrical faults. For instance, in an electric vehicle charging station, isolation safeguards both the charger and the vehicle’s battery management system from power surges.

Ground loops, which can introduce unwanted noise or damage equipment, can be eliminated through isolation. This ensures stable operation and accurate measurements, maintaining system integrity over time.

In industries where uptime is critical, such as automated production lines, isolation helps protect key components from voltage spikes and electrical disturbances, minimizing shutdowns and maintenance costs.

Electrical Isolation Solutions

Electrical isolation is fundamental to achieving safe, reliable, and efficient operation in high-voltage electrical systems. By preventing direct electrical contact and blocking interference, isolation ensures the longevity of equipment and the safety of personnel. It also protects critical components from voltage spikes and reduces ground loop noise, which is essential for maintaining data integrity in sensitive applications like battery monitoring and industrial automation.

Selecting the appropriate isolation method and level depends on the specific requirements of the application. Reinforced isolation, for instance, is essential in high-risk settings, while basic isolation suffices in lower-risk, consumer-oriented applications. Each solution also supports compliance with safety standards, helping to reduce liabilities while adhering to UL, IEC, and EN regulations.

Ultimately, electrical isolation is not merely a safety measure, it is a way to ensure a system is efficient and resilient. By implementing the right isolation, organizations ensure both operational stability and compliance, helping future-proof systems as they evolve to handle more demanding, high-voltage applications.

Contact Us today to learn more about our High Voltage Solutions.