Solutions / High Voltage / Hydrogen Energy Storage

Hydrogen Energy storage

Voltage measurement and isolation in electrolyzers & fuel cells

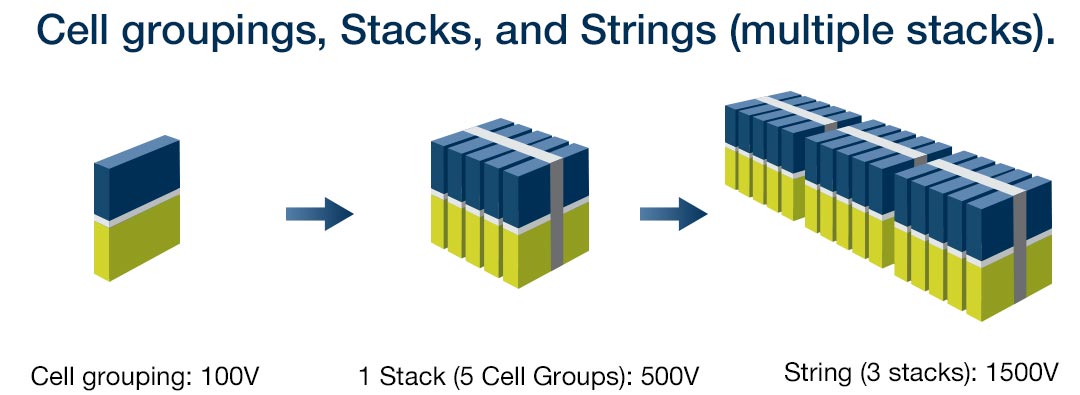

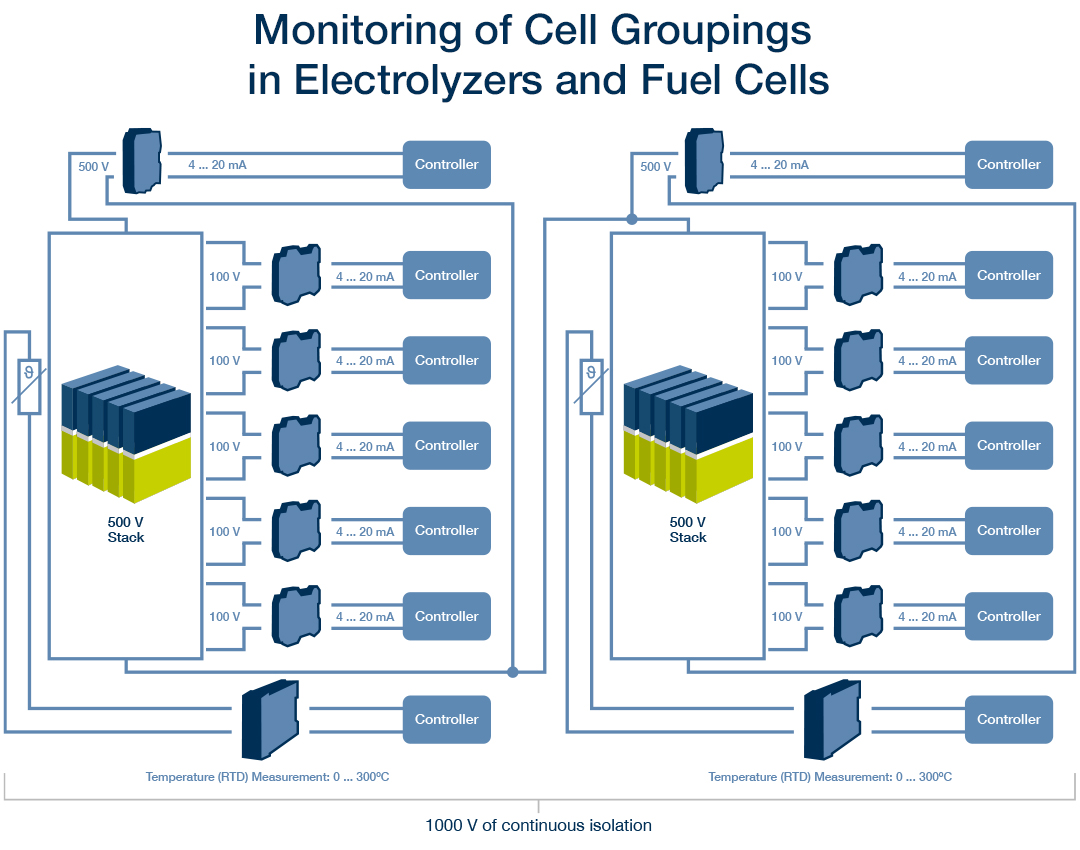

Hydrogen offers an exciting opportunity for decentralized renewable energy storage due to its high energy density. Electrolyzers that produce hydrogen and fuel cells that convert hydrogen to electricity are constantly evolving in performance. To maximize efficiency and ensure process reliability, continuous evaluation of the cells within these systems — often integrated in large numbers — is essential. Reliable transducers are critical for safely isolating high potentials while measuring DC voltage, current, and temperature with precision.

This is where the partnership between AmeriChem Systems (ASI) and Knick Interface (KI) shines. ASI, as the system builder, provides end-to-end expertise in system integration, offering simplified installation and conversion of analog inputs to Ethernet, along with turnkey design and fabrication capabilities. By consolidating components into efficient packages, ASI enhances the overall performance and reliability of the solution.

Knick Interface transducers, thanks to their isolation capabilities, precision, and long-term stability, are the ideal solution for measuring voltage, current, and temperature in electrolyzers and fuel cells at the cell, stack, or string level. With continuous isolation up to 4800 VDC and a gain error as low as 0.1% of the measured value, Knick products stand up to the most demanding hydrogen applications. Their maintenance-free design, thanks to no recalibration requirements over their entire service life, further enhances their reliability. Additionally, many models offer configurable input/output ranges for added flexibility, along with compact housing and standard DIN-rail mounting, making installation a breeze—especially with ASI’s system-building expertise behind the scenes.

The ASI & KI partnership is a perfect combination of cutting-edge measurement technology and expert system design, delivering a solution that meets the evolving needs of hydrogen energy storage.

Related Solutions: High Voltage Plant Safety

Industries We Serve

Refineries + Offshore Applications

Industrial Application

- Hydrocarbon / Petrochemical

- Paper Mills

- Chemical Plants

- Steel Manufacturing

- Water / Wastewater Treatment

- Heavy Industry

- Semiconductor Manufacturing

Food + Beverage

- Utilities / Water Treatment

- Meat Processing

- Bottling / Filling

Research + Development

- Test Stands

Pharmaceutical

- Lab Equipment

- Essential Oil Extraction

Electric + Generating Plants

- Fossil

- Gas Fired

- Coal Fired

- Oil Fired

- IGCC

Nuclear

Renewables

contact us.

Are you looking for information on an existing project, a solution for a unique problem, or a custom quote? Fill out this form and we’ll get back to you right away.

Call us: +1 630 495 9300