Boom or Bust? Don’t let your next process plant expansion give you a stiff neck and a busted budget!

Processing plants in the food, chemical manufacturing, energy and pharmaceuticals industries are growing while other sectors are struggling. This has many plant managers wondering how to expand their operations with a limited footprint and other concerns.

Modular Process Systems in Chemical Manufacturing

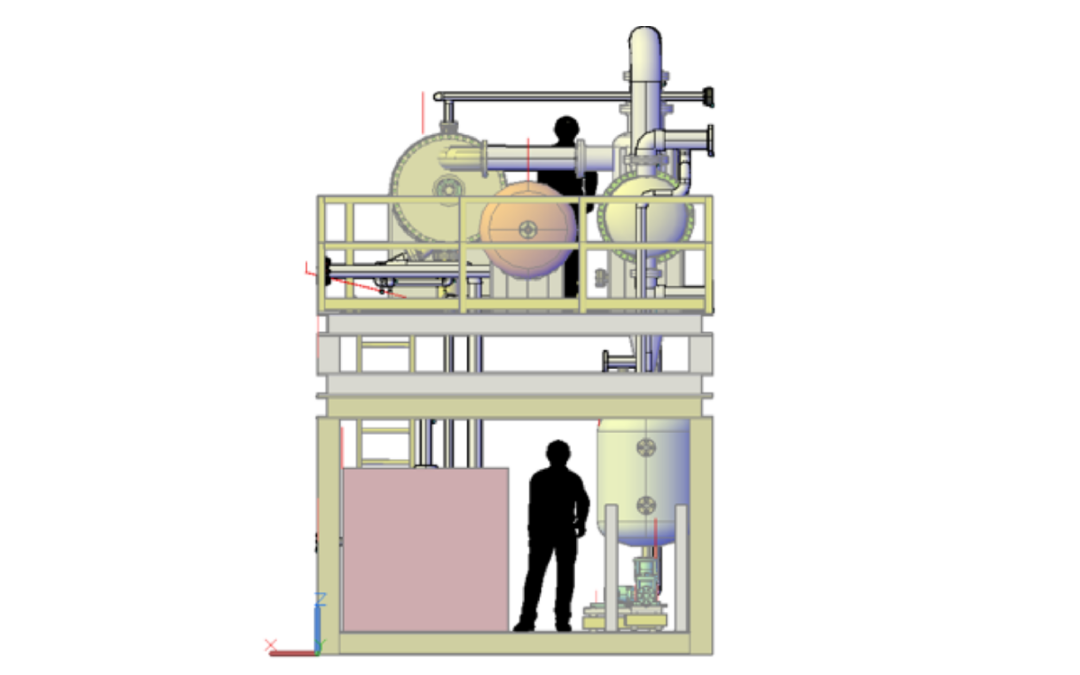

Modular process systems have become increasingly popular in the chemical manufacturing and energy industries, particularly when it comes to plant expansions. These practices are starting to spill-over into the food, pharmaceutical and other industries. These systems offer a range of benefits that can make the expansion process more efficient, cost-effective, and safe.

One major benefit of using a modular process system is flexibility. With a traditional, non-modular approach to plant expansions, the entire process must be shut down and rebuilt to accommodate the new equipment and processes. This can be costly and time-consuming, and it can also result in significant downtime for the plant. With a modular approach, individual modules can be added or removed as needed, allowing for a more incremental expansion process. This can also make it easier to test new processes and equipment before fully integrating them into the plant.

Multiple Modular Systems Assembled Into One Pilot Plant

Another benefit of using a modular process system is scalability. As a company grows and expands its operations, a modular system can be easily scaled up or down to accommodate the changing needs of the business. This can help to reduce costs associated with building and maintaining a large, inflexible process system.

Modular systems also offer benefits when it comes to maintenance and repair. In a traditional process system, a malfunction or breakdown in one part of the process can bring the entire system to a halt. With a modular system, individual modules can be isolated and replaced as needed, minimizing downtime and disruption to the overall process.

In addition to these benefits, using a modular process system can also improve safety in the manufacturing plant. Because the systems are pre-engineered and pre-fabricated, they are built to the highest safety and quality standards. This can help to reduce the risk of accidents and incidents in the plant.

Overall, using a modular process system during plant expansions can offer a range of benefits, including flexibility, scalability, efficient maintenance and repair, and improved safety. These benefits can help to make the expansion process more efficient, cost-effective, and safe for companies in the chemical manufacturing industry.

Let’s talk about how to make your next plant expansion project a success!

Contact ASI today to start your next plant expansion project

#asi #wecandothat #americhemsystems #plantexpansion #processautomation #processengineering

Did you like this post? Visit our Articles Page www.AmeriChemSystems.com/articles and follow us on LinkedIn: @AmeriChemSystems. To read more about technology, innovation, and industry insights, just click the ‘Follow’ button at the top of this page.

Here are some of my previous LinkedIn insights:

Has your Rail Tank Car filling got you going off the rails?

Custom Automation – Machine Highlight: Automatic Filling Machines

Improving legacy process systems: Turn your data reporting wishbone into a backbone

Did you know that most companies get their process expansion projects backwards?