Solutions / High Voltage / High Voltage Plant Safety

HIGH VOLTAGE PLANT SAFETY

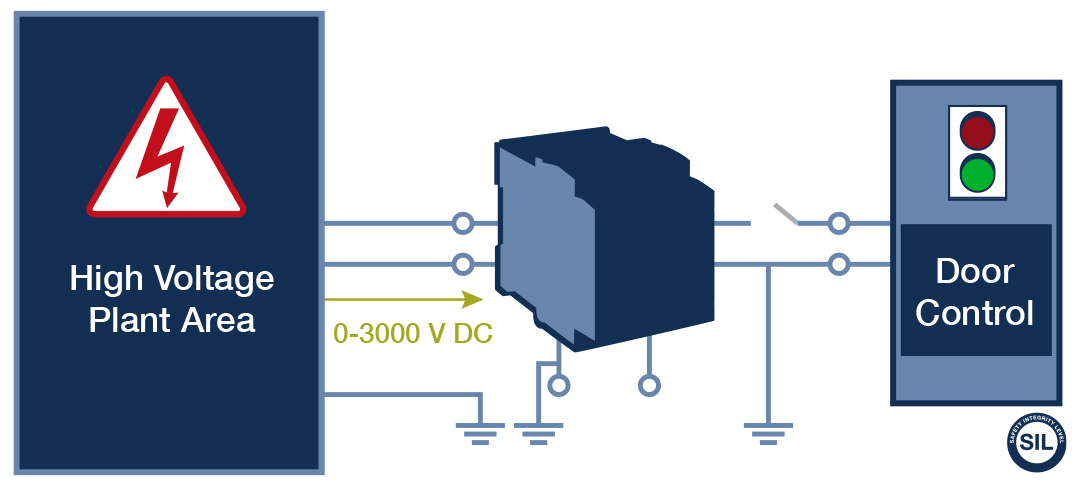

The partnership with AmeriChem Systems (ASI) takes this one step further by integrating KI’s electrical measurement hardware into full systems that enhance safety and operability. ASI provides turnkey solutions that include area interlocks, alarming, and personnel notifications, ensuring that high-voltage zones are securely monitored. ASI’s expertise in integrating Safety PLCs or SIL safety-rated controllers into plant networks ensures seamless handshakes between upstream and downstream systems, providing additional safety and operational efficiency.

ASI’s ability to consolidate these components into efficient packages makes integration into new or existing systems a streamlined process. From voltage monitoring and isolation to full system integration with alarm systems and personnel safety protocols, ASI ensures a reliable and cost-effective solution. For applications requiring functional safety, KI also offers transducers with SIL 2 certification, (or SIL 3 in redundant configurations), ensuring compliance with the highest safety standards.

By leveraging the strengths of ASI & KI, plants can achieve high-voltage safety with confidence, knowing they are equipped with systems designed for protection, precision, and ease of integration.

Related Solutions: Hydrogen Energy Storage

Voltage measurement and isolation in electrolyzers & fuel cells

Hydrogen offers an exciting opportunity for decentralized renewable energy storage due to its high energy density. Electrolyzers that produce hydrogen and fuel cells that convert hydrogen to electricity are constantly evolving in performance. To maximize efficiency and ensure process reliability, continuous evaluation of the cells within these systems—often integrated in large numbers—is essential. Reliable transducers are critical for safely isolating high potentials while measuring DC voltage, current, and temperature with precision.

Industries We Serve

Refineries + Offshore Applications

Industrial Application

- Hydrocarbon / Petrochemical

- Paper Mills

- Chemical Plants

- Steel Manufacturing

- Water / Wastewater Treatment

- Heavy Industry

- Semiconductor Manufacturing

Food + Beverage

- Utilities / Water Treatment

- Meat Processing

- Bottling / Filling

Research + Development

- Test Stands

Pharmaceutical

- Lab Equipment

- Essential Oil Extraction

Electric + Generating Plants

- Fossil

- Gas Fired

- Coal Fired

- Oil Fired

- IGCC

Nuclear

Renewables

contact us.

Are you looking for information on an existing project, a solution for a unique problem, or a custom quote? Fill out this form and we’ll get back to you right away.

Call us: +1 630 495 9300