Choosing the Right Fit: Custom vs. Standard Chemical Feed Systems

If you’re planning to install a chemical feed system, one big question often comes up early: Do you need a custom chemical feed system, or will a standard skid do the trick?

Getting the answer right matters. A system that doesn’t fit your process can cause major issues, like downtime, safety risks, or expensive redesigns. That’s why AmeriChem Systems helps engineers and buyers understand when to go custom—and when a standard setup is just fine.

What’s the Difference?

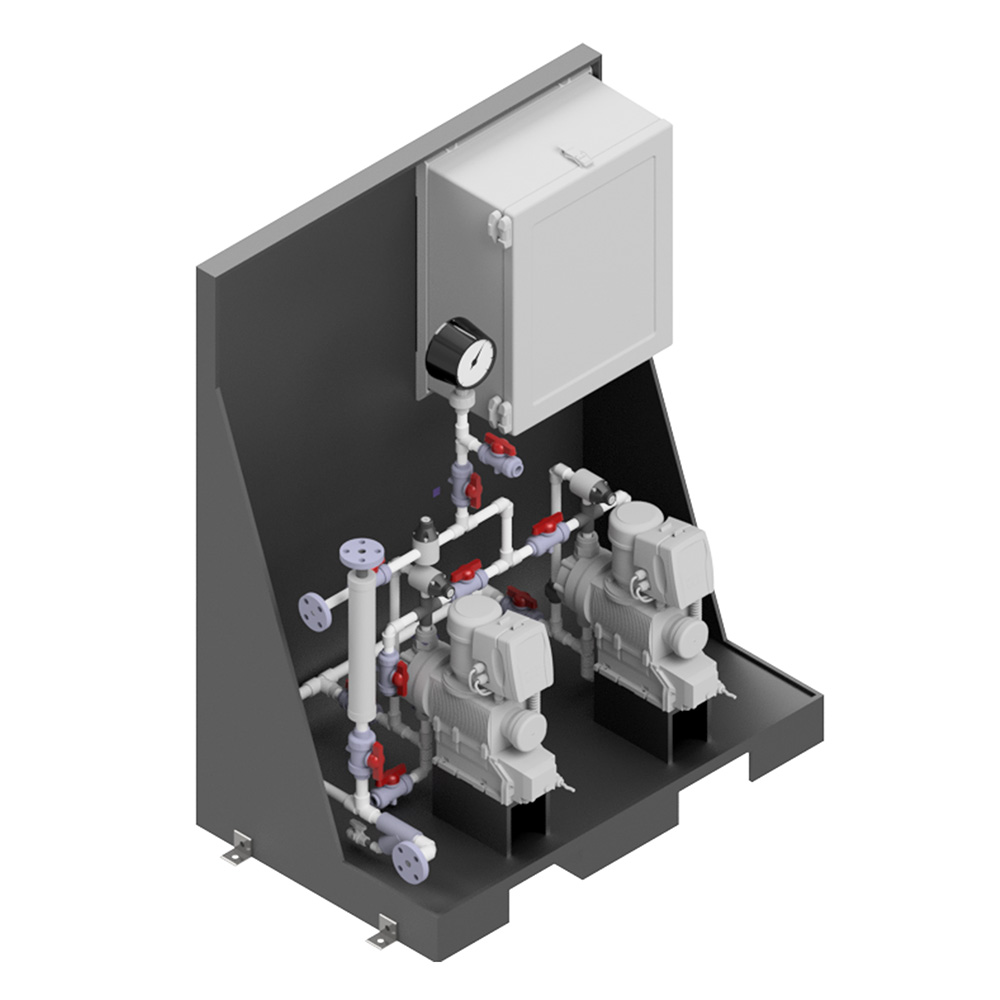

A standard feed system follows a set layout, size, and component list. It’s faster to quote, quicker to build, and usually more affordable upfront.

A custom chemical feed system, on the other hand, is designed specifically for your plant. That means the layout, materials, automation, flow rates, and safety features are tailored to your specs.

Michael Perry, National Sales Manager at AmeriChem, explains: “Custom systems are all about fit. Whether it’s unusual chemicals, tight spaces, or special controls—custom is often what’s needed to make it all work reliably.”

When a Standard System Is Enough

Sometimes standard works great. This is especially true in municipal water treatment projects where requirements are clear and consistent. These jobs often repeat the same specs and don’t need custom layouts or high-level automation.

In these cases, a standard system can save time and budget without risking performance.

When You Need a Custom Chemical Feed System

A custom chemical feed system becomes essential when:

- Space is tight or nontraditional

- You’re using harsh or unique chemicals

- Flow or pressure requirements are unusual

- The system needs to integrate with other automated controls

- Safety or compliance standards are complex

AmeriChem’s team often helps clients avoid the trap of trying to “make a standard system work” in situations that really call for a custom design.

The Hidden Risks of “Close Enough”

Trying to force a standard system into a custom need is a common mistake. It can lead to oversized pumps, incorrect materials, or clunky layouts that are hard to maintain.

“The biggest risk is not realizing your process is unique until the system fails,” says Perry. “We’d rather guide you up front than fix costly problems later.”

How AmeriChem Guides the Decision

AmeriChem starts with questions, not just specs. They ask about space, chemistry, maintenance, automation, environment, and more. Then they guide the customer toward a solution that’s safe, reliable, and cost-effective over the long haul.

Their goal? A chemical feed system that performs, not just one that ships quickly.

Don’t Settle for the Wrong Fit

Before you invest in a system, ask: Is this a job for standard—or is a custom chemical feed system the smarter move?

AmeriChem has helped hundreds of engineers make that call, with real-world insight and ISO-backed process. Reach out early and build it right.

Did you like this post? Visit our Articles Page and follow us on LinkedIn: @AmeriChemSystems. To read more about technology, innovation, and industry insights, just click the ‘Follow’ button at the top of this page.

Here are some of my previous LinkedIn insights:

Design of Suction Piping for Centrifugal Pumps

Boom or Bust? Don’t let your next process plant expansion give you a stiff neck and a busted budget!

Has your Rail Tank Car filling got you going off the rails?

Custom Automation – Machine Highlight: Automatic Filling Machines

Improving legacy process systems: Turn your data reporting wishbone into a backbone