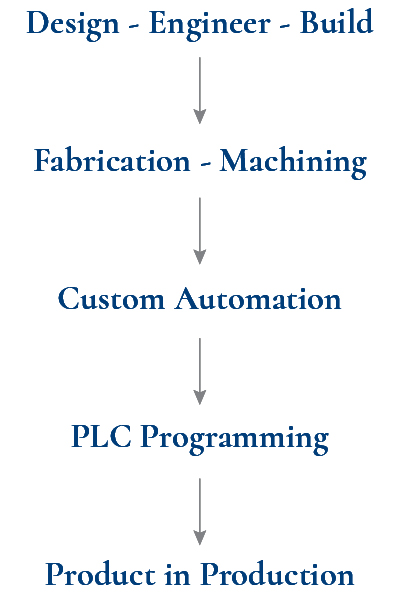

The ASI Automation Group (AG) provides complete Control Systems Integration

Our engineers work with the latest versions of mechanical and electrical design software to optimize the configuration and size of your system. These capabilities, coupled with our expert assembly team, allow us to feel confident that we will build you the most energy, space, and cost effective system available for your application.

We can provide complete custom control panel systems to meet your requirements. Or we can assist your team with any stage of your internal process — from design and engineering to programming and fabrication.

Commissioning services for the following items are also available:

- PLC Panels

- Variable Speed Drives

- Operator Consoles/HMI Panels

- Motion Control Upgrades

- Component Integration, and

- Motor Controls

Let’s Get Started

Use the form below to contact the ASI Automation Group to discuss your custom system.

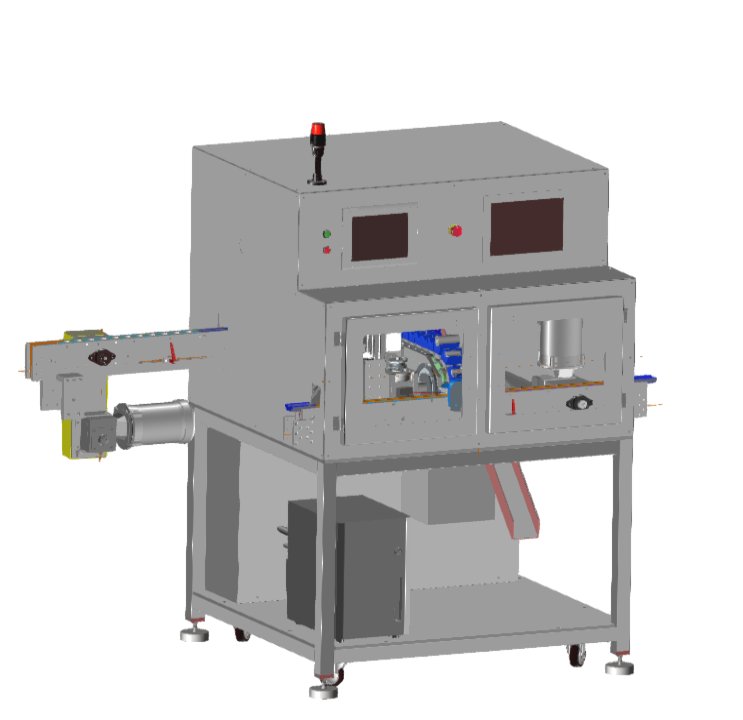

Custom Automated Machine Examples:

Automatic Filling Machine

Automatic Fillers provide accurate filling of liquid or semi-liquid products into jug or bucket containers ranging from 0.5 – 6 gallons (2-25 L). Printer automatically prints filled weight for manual application.

High-Speed RFID Systems

Filling Machine RFID System

State of the art traceable components and systems to reduce waste and downtime associated with the filling process. This high-speed RFID reader records each RFID tag present (rated up to 3,000 tags per minute) in the filler vent tubes or traceable pills in real-time during the filling process.

Laser Marking Machines

High-Speed Laser Marking Machine

High-speed laser marking machine with small footprint and infeed and outfeed conveyors. With a remarkable capacity of marking up to 3 parts per second, it incorporates pre-mark inspection and post-marking inspection, ensuring precision and quality throughout the process.

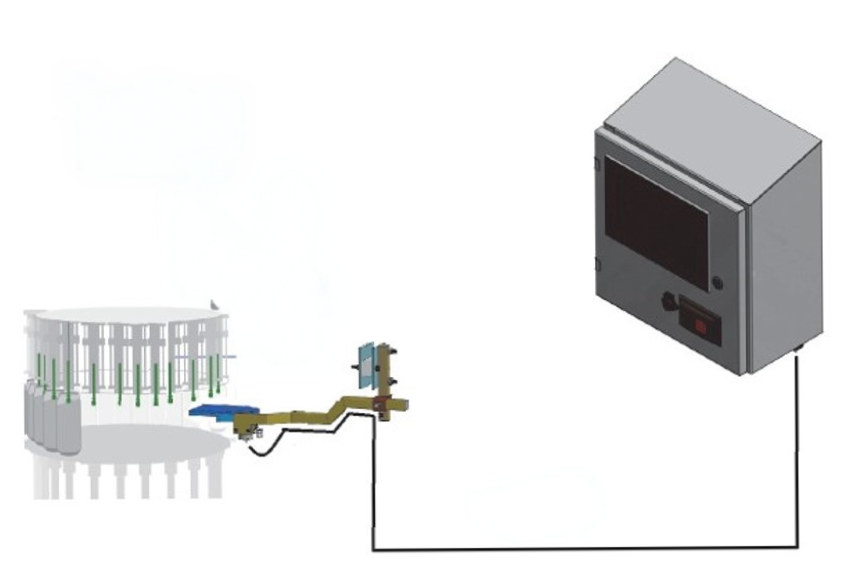

Automatic Flow Sensor Control Enclosure

Automatic Flow Sensors for liquid and gas, a new technology with various clamp-on types to enable stable flow rate measurement with no pipe modification. These devices can be used on small tubes to large pipes as well as environmental resistant and sanitary types. ASI’s relay control box with local inputs and outputs for the plant ERP and MES system or local PLC.

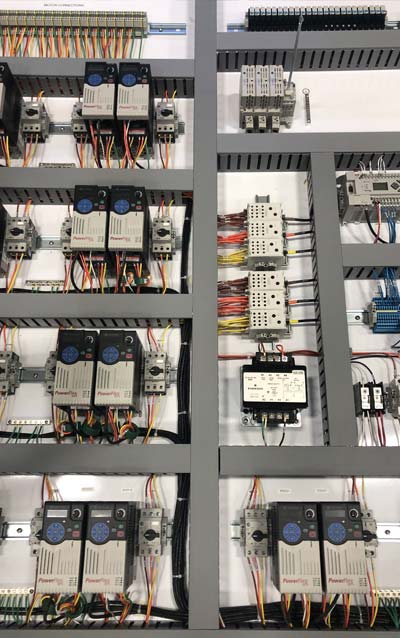

Electrical Enclosure with Purge

PLC control panel enclosure with purge system for classified environment. Automatic packaging process control with food and explosion proof certification requirements. HMI panel for location control with local inputs and outputs. Remote network connections for plant ERP and MES system.